The Most Effective Storage Solution for Uncut Hydraulic Hose

Q. What is the best way to store uncut hydraulic hose?

A. Uncut Hydraulic Hose is best stored in a High-Density Hose Cabinet, as close to the hose cut-off saw as possible. The Hose Cabinet, where possible, should be designed so that the hose can be unwound without tangles or kinks, and can then be wound back up to protect the hose.

BAC Systems is the world leader in uncut Hydraulic Hose Storage with unique hose storage solutions being used on multiple continents. These solutions have been refined over many decades and reflect a combination of the ergonomics of handling hoses balanced with the need to keep as much hose as possible as close to the cut-off saw as possible.

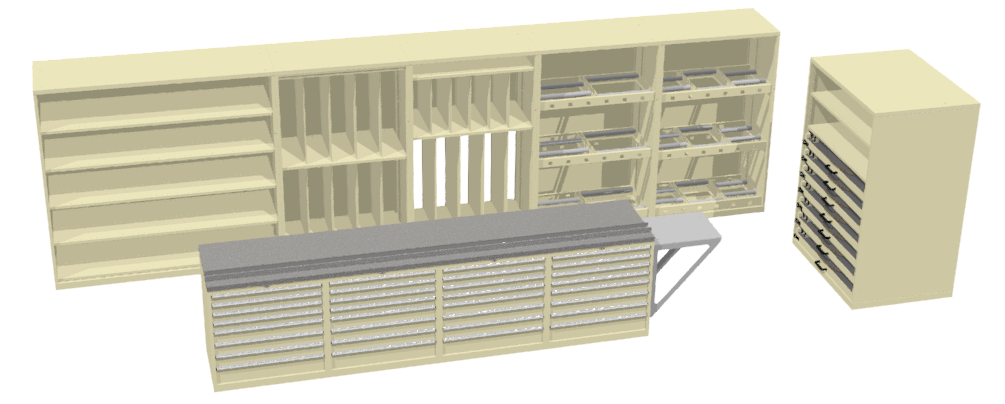

The BAC Systems range of Hydraulic Hose Storage Modules achieve just this. These simple, refined and effective storage modules are free-standing cabinets which you can place around your cut-off saw to best effect. These cabinets are a far more efficient way to store hoses compared to using pallets on rack, structures bolted to the pallet rack, or plain shelves, as the BAC Solutions offer unique locations for each hose, easy access in seconds to that hose, and all while using a far smaller footprint, and with no forklifts required.

Consider this: by upgrading your workshop from storing your hose on pallets or on a bit of pipe welded beneath your pallet rack, to a BAC Hose Storage Bundle of modules, you no longer have to walk that extra 6-20 metres, find the forklift, access the rack, take the hose off and untangle it, (common cut process in here), reorder the hose onto the pallet, return it to the rack, and return to your hose making area. If, along the way, you have avoided getting caught in a conversation with one of the storesmen, then all of these extra steps would have cost you, perhaps, 5 minutes of unnecessary materials-handling time. Now, consider that you may have to do this 10 times a day in a small hose workshop. You have just wasted 50 minutes, multiplied by 5 days a week and 48 working days a year, which comes to 200 hours a year saved. Multiply that by your labour rates and your insurances bills, etc, and you will find that your are "materials-handling" your money down the drain!

There are many enterprising foremen who have attempted to fabricate different solutions for hose storage, but they never achieve a reasonable density of hose near the saw, even if they improve hose handling, or, they have plenty of hoses near the saw but there is no provision for safe handling. With the BAC range of Hose Storage Modules, you achieve both key goals.

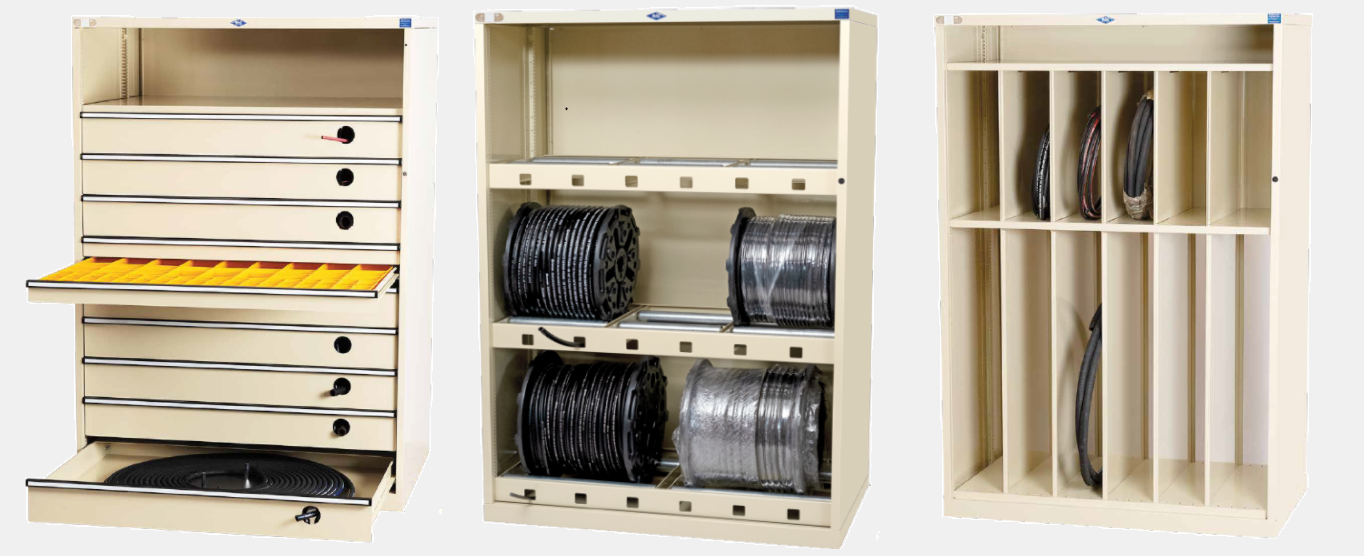

BAC Hose Reel Modules store heavy hose reels on a series of conveyor rollers. This allows them to be unwound very easily and for overdraw to be rewound just as easily. When a reel is emptied, you don't have to lift multiple reels on a single spool to change it - simply pick-up the spent reel and roll a new one into its place.

BAC Hose Drawers are designed for hoses that come pre-packaged in a flat reel. Simply rip off the cardboard carton, sit the flat bundle on the turntable inside the drawer, and cut the straps. In seconds, you are ready to unwind the hose without any mess or kinks.

BAC Hose Bundle Modules are for those larger bundles that are too large for the Hose Drawer. The bundles are easily stored on their edge in the vertical slots which gives them individual locations on a very small footprint.

Contact the BAC Technical Sales Team today to find out about our standard Hose Making Workshop Bundles, to talk about the efficient workflow in hose-making with BAC Hose Storage Equipment, or to arrange a complementary site survey.